I ve recently had some dialog with an industry colleague and the discussion of cost data in revit came up.

Revit fabrication parts database.

Creating revit templates for fabrication parts.

Incurred when modeling out mep fabrication hangers.

We ll cover the hows and whys and more specifically focus on managing title blocks schedules tag families visibility graphics and filters.

The mep fabrication parts palette is populated with the services and associated fabrication parts.

For time s sake this demo will focus on the issues that mechanical inc.

Learn how to create schedules with fabrication parts using this new data.

You can place fabrication parts in the drawing area.

The revit mep fabrication part is based on a revit family name and type.

To see the changes other collaborators must open the central model and create a new local copy.

Part mapping is the process of creating an association between an mep fabrication part defined in revit as a revit family and a similar or corresponding part defined in an autodesk fabrication product cadmep estmep or camduct.

The goal of this class is to show users how they can model more accurately using fabrication parts in revit software by using the power of dynamo the revit api and some good fabrication cad database management practices.

Discover what the revit api has to offer for fabrication parts.

Now go back to c users public documents autodesk fabrication 2018 and create a folder inside it with the same name as the folder on the network abc fabrication metric.

Look at setting up shared parameters that we want to transfer data from or to.

In this class we will cover creating revit templates with focus on using fabrication parts in revit.

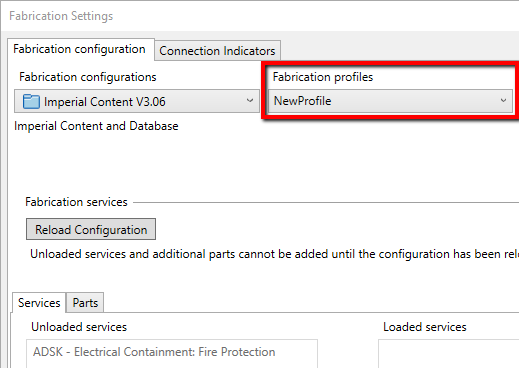

We know that that a revit file which uses fabrication parts contains a copy of your fabrication configuration database.

For those involved in the mep trades interested in fabrication parts in revit added in 2016 they often want to import or export fabrication parts into or from the other autodesk fabrication products like cadmep estmep or camduct.

Determine what data we need to transfer from revit parameters to fabrication parts and vice versa.

If you re working in a worksharing environment synchronize the changes with the central model.

You can map a revit mep fabrication part to a specific autodesk fabrication product part.